ABOUT US

OUR STORY

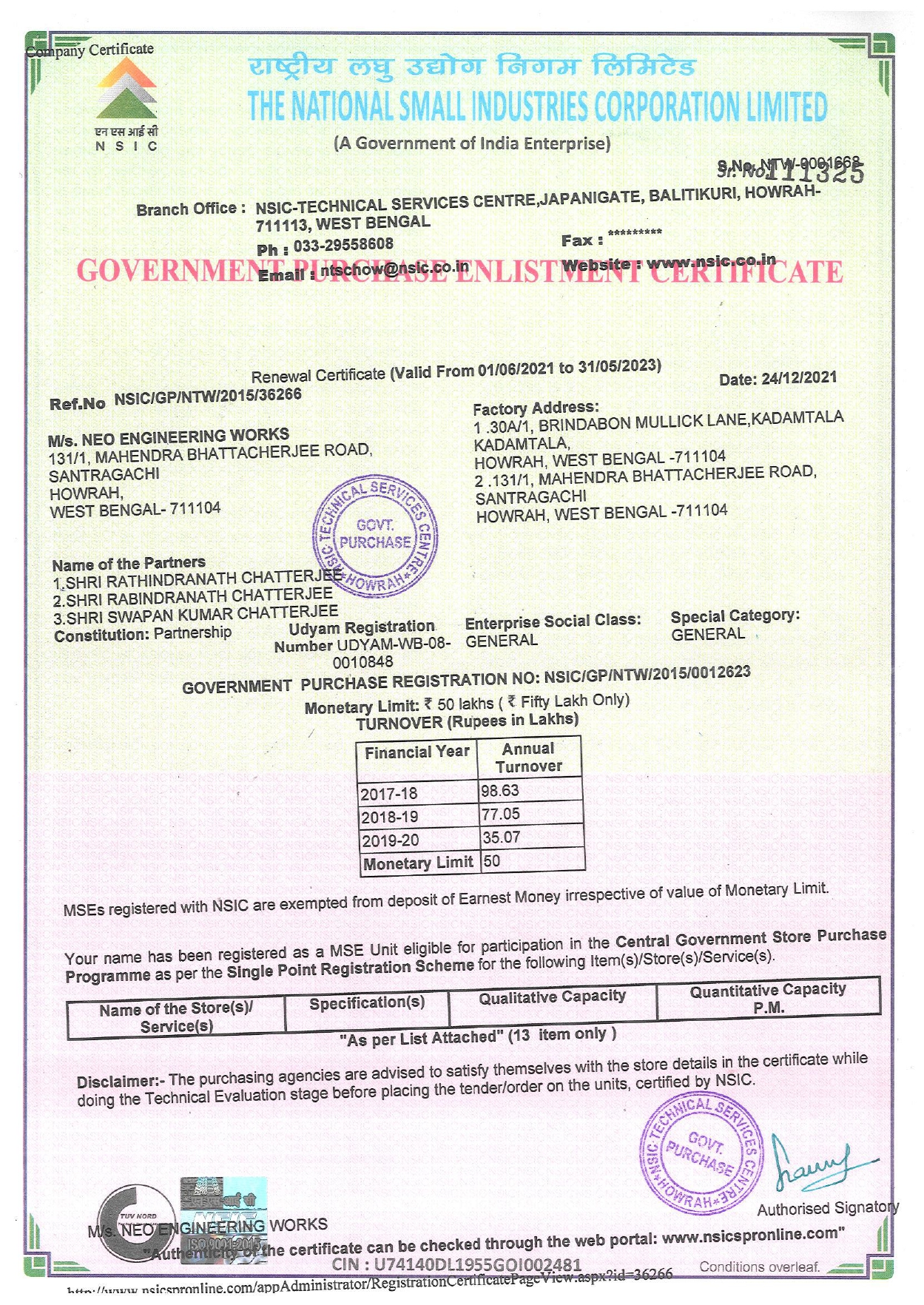

NEO ENGINEERING WORKS is a manufacturing organisation in the small scale sector , engaged in the manufacturing of spares of Diesel Locomotives. It is a S.S.I. and N.S.I.C. registered unit . The works is located in the heart of West Bengal’s industrial activities i.e., at Howrah , which is well known for its skilled labour force and long history of manufacturing operations. The company was incorporated and registered in 1971 as a proprietorship business. After that in the year 1986 this company converted as a partnership business.

The company started its activity through manufacturing of jute mill spares. With the addition of plant & machineries , the volume of production is gradually increased and soon it offered its products to the Indian Railways . The business relation with railways developed through deliveries to different divisions of railways spread all over the country.

Side by side it started developing certain special product for diesel locomotive, e.g. Governor Drive and it’s spares. Soon the organisation established itself as manufacturer and supplier of these products to various divisions of Indian Railways . Presently Neo Engineering is a well known name to all the major railways as a manufacturer of spares of Diesel Locomotives. As for the railways company manufacture around 500 different types of spare parts for the locomotive engines to formerly DLW (Diesel Locomotive Works) design, “ALCO” (American Locomotive) design and “GENERAL MOTORS” (EMD) design.

Other than railways, the company also supplies same spares to some other large organisations , who use diesel locomotives for their own operation. The major customers are DLW (Diesel Locomotive Works – Varanasi), DMW (Diesel Loco Modernisation Works – Patiala) and all Indian Zonal Railways, SAIL, NALCO, NTPS, Port trust etc.etc. Company also export locomotive spares to country like USA & Canada, Vietnam etc. directly and via RITES Export/India.

Since inception Neo Engineering has given very high importance towards maintenance of quality . At every stage of production the quality is ensured through proper quality planning . Continuous efforts are directed towards improvement in quality of job at incoming , in process and finishing stages of operation .

The customers have their own checking and approval mechanism for the supplies taken . A regular interaction exists between the company and the customers as regards the quality and delivery . The products and system have to pass through thorough assessment of Railway inspection authorities .

The company believes in participative management and a very harmonious industrial relation is maintained.

The product profile of the company has been listed separately and a review is done every six months to ensure any modification needed in the product range.

TOP RATED

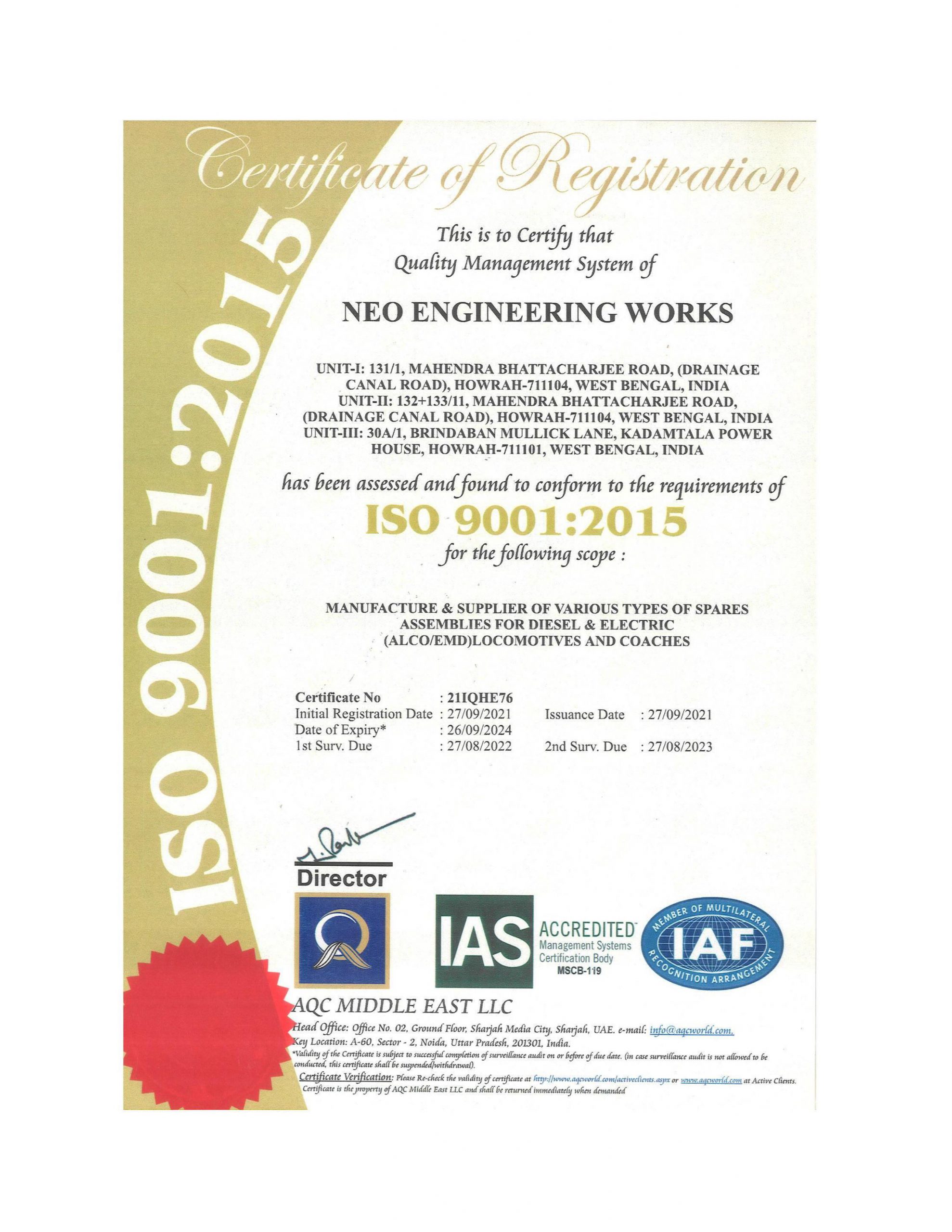

Neo Engineering Works was incepted in the year 1971. Armed with an ISO 9001:2015 certificatio.

BEST QUALITY

We are a renowned manufacturer, supplier and exporter of a premium range of Railway Fittings.

LOW COST

We provide better quality products under minimum cost, We understand the value of our client’s wealth.